Location:Home / Product / Control Valve / Pneumatic sleeve regulating valve

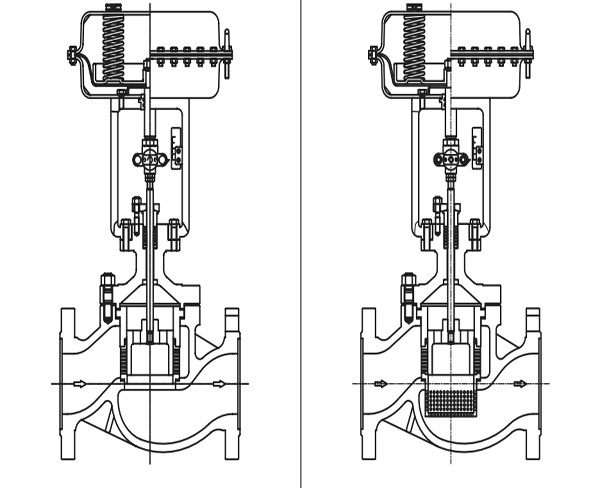

Pneumatic sleeve regulating valve

Pneumatic control valve is powered by compressed gas, with a pneumatic diaphragm head as the actuator, and driven by accessories such as valve positioner, converter, solenoid valve, holding valve, gas storage tank, gas filter, etc., to achieve on/off or proportional adjustment. It receives control signals from industrial automation control system to adjust various process parameters of pipeline media, such as flow rate, pressure, temperature, liquid level, etc. The characteristics of pneumatic control valves are simple control, fast response, and inherent stability, without the need for additional explosion-proof measures

Product Features:

Pneumatic sleeve regulating valve adopts sleeve guidance and pressure balanced valve core, suitable for situations with large pressure difference. By replacing the upper valve seat with a balanced sealing ring, the traditional sleeve double seat valve structure is transformed into a sleeve single seat structure, greatly improving the leakage level of the sleeve valve. The valve core utilizes a pressure balanced structure with low opening and closing force. The working condition of high pressure difference can be controlled by a smaller actuator thrust. Widely used in fluid control of medium and low temperature, medium and low pressure pipelines that require good dynamic stability. Good sealing performance and large allowable pressure difference. Sleeve guide, with a large guide area, good stability, compact structure, can quickly replace valve components online, high maintenance efficiency, and save manpower and time. The balanced valve core structure ensures that the required actuator thrust is small.

Technical Specifications:

| Nominal Diameter (mm) | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | ||||

| seat diameter (mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||

| Rated flow coefficient Kv | straight line | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | 1000 | 1600 | |||

| equal percentage | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 900 | 1440 | ||||

| Nominal Pressure MPa | 0.61.64.06.4 | |||||||||||||||

| itinerary mm | 16 | 25 | 40 | 60 | 100 | |||||||||||

| flow characteristics | Straight line, equal percentage, quick opening type | |||||||||||||||

| medium temperature ℃ | -40-230 ℃ (normal temperature type), heat sink 230-450 ℃ (medium temperature type), special order -100-600 ℃ | |||||||||||||||

| Flange Standard | Compliant with JB78-59 and JB79-59 standards, can be ordered and produced according to JB/79.1-94, JB/79.2-94, ANSI, JIS, DIN and other standards | |||||||||||||||

| Valve body material | PN(MPa) | 0.6,1.6 | WCB(ZG230-450)CF3CF8CF8M | |||||||||||||

| 4.0,6.4 | WCB(ZG230-450)、ZG1Cr18Ni9Ti、ZG0Cr18Ni12Mo2TiCF8CF8M | |||||||||||||||

| Valve type | Straight through single seat cast ball valve | |||||||||||||||

| Valve core material | 1Cr18Ni9、0Cr18Ni12Mo2Ti CF8 CF8M | |||||||||||||||

| Upper valve cover form | Ordinary type (constant temperature type), hot plate type (medium temperature type), low temperature type | |||||||||||||||

| Adjustable ratio R | 50:1 | |||||||||||||||

| Air source connector | M16×1.5 | |||||||||||||||

Main technical parameters of the executing agency:

| model | ZHA(B)-22 | ZHA(B)-23 | ZHA(B)-34 | ZHA(B)-45 |

| effective area cm2 | 350 | 350 | 560 | 900 |

| itinerary mm | 16 | 25 | 40 | 60 |

| Spring range KPa | 20~100(standard);40~200;80~240;20~60;60~100 | |||

Ordering instructions: 1; Please provide design drawings and detailed parameters as much as possible, and our valve specialist Jia will review and control them for you. Thank you for visiting our website【 http://www.zjlnv.com/ 】If you have any questions You can call us and we will do our best to provide you with thoughtful service. Sales hotline: 13780162376.

relevant information

Tel

0577-67113630 15857947467Add

Puyi Village Jiangbei Street Yongjia County Wenzhou City Zhejiang Province

Scan