Location:Home / Product / Ball Valve / Turbine fully welded electric flange ball valve

Turbine fully welded ball valves are widely used in various fields. Its good quality and high-performance stability cannot be achieved by ordinary cast steel ball valves, and its service life is much longer than that of cast steel ball valves. Fully welded ball valves are widely used in various pipeline equipment such as urban gas, urban heating, petrochemicals, shipbuilding, steel, pressure regulating stations, power plants, etc. The fully welded ball valve can operate reliably for a long time, requires maintenance, is easy to install, and the installation of the valve is more convenient.

Characteristics of fully welded turbine ball valve:

(1) The fully welded ball valve has a compact structure, reliable sealing, simple structure, and easy maintenance. The sealing surface and spherical surface are often in a closed state, which is not easily marked by the medium (electric or pneumatic) for whole machine testing (to prevent vibration caused by transportation from affecting performance). (2) Only after passing the inspection can it be installed on the wire (wiring should follow the electric actuator circuit diagram).

(3) Before connecting to the pipeline, it is necessary to flush and remove any remaining impurities in the pipeline (which may damage the valve seat and ball).

(4) During installation, please do not use the actuator part of the valve as a lifting point to avoid damaging the actuator and accessories.

(5) This type of valve should be installed in the horizontal or vertical direction of the pipeline.

(6) The pipeline near the installation point should not have any low hanging or external force bearing phenomenon. Pipe supports or supports can be used to eliminate the deviation of the pipeline.

(7) After connecting to the pipeline, please cross tighten the flange connection bolts with the specified torque.

Features: Integrated welded ball valve, no external leakage or other phenomena Due to the carbon fiber reinforced PTFE seal and butterfly spring of the valve seat, it has strong adaptability to changes in pressure and temperature, and any leakage may occur within the marked pressure and temperature range. The machining process of the sphere is tracked and detected by new computer detectors, so the machining accuracy of the sphere is high.

Due to the fact that the valve body material is the same as the pipeline material, there will be no uneven stress, and there will be no deformation due to earthquakes or vehicles passing through the ground. The pipeline is resistant to aging. The sealing ring body is made of RPTFE material with a carbon content of 20%, ensuring complete zero leakage (0%).

Directly buried welded ball valves can be directly buried underground without the need to build large valve wells. Only small shallow wells need to be set up on the ground, greatly saving construction costs and project time. The length of the valve body and the height of the valve stem can be adjusted according to construction and design requirements. The processing accuracy of the sphere is very high, the operation is easy, and there is no adverse interference. Using good raw materials can ensure a pressure of PN25 or higher.

Compared with products of the same specifications in the same industry, the valve body is small and has a beautiful appearance. The service life of the valve is over 15 years while ensuring normal operation and use.

Installation: All Sko steel ball valves are welded at the end using electric welding or manual welding. Overheating of the valve chamber should be avoided. The distance between the welding ends should not be too short to ensure that the heat generated during the welding process does not damage the sealing material. During the installation process, all valves should be opened.

Material of fully welded ball valve for turbine:

1. Valve body: carbon steel ST37.0, A106-B; Steel No. 20

2. Sphere: Stainless steel 304 or 316

3. Valve stem: 2Cr13

4. Valve stem seal: Perfluorosilicone adhesive

5. Sphere seal: RTFE (PTFE+C)

Application of fully welded ball valve for turbine:

1: Urban gas: gas output pipelines, main and branch supply pipelines, etc.

2: Central heating: large heating equipment output pipelines, main lines, and branch lines.

3: Heat exchanger: opening and closing of pipelines and various circuits.

4: Steel plant: various fluid pipelines, exhaust gas discharge pipelines, gas and heat supply pipelines, fuel supply pipelines.

5: Various industrial equipment: various heat treatment pipelines, various industrial gas and heat pipelines.

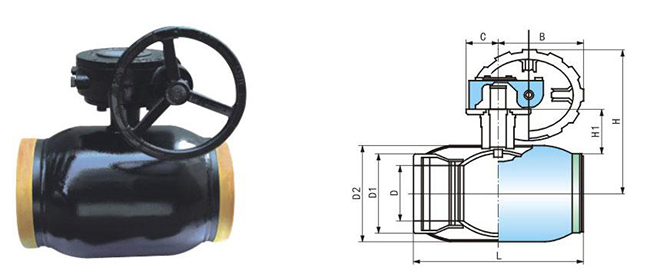

Dimensions related to fully welded ball valves for turbines:

| DN | PN | L | D | D1 | D2 | H | B | H1 |

| 10 | 40 | 230 | 10 | 17.2 | 33.7 | 98 | 145 | 22 |

| 15 | 40 | 230 | 10 | 21.3 | 33.7 | 98 | 145 | 22 |

| 20 | 40 | 230 | 15 | 26.9 | 42.4 | 103 | 145 | 23 |

| 25 | 40 | 230 | 20 | 33.7 | 48.3 | 118 | 145 | 34 |

| 32 | 40 | 260 | 25 | 42.4 | 60.3 | 121 | 145 | 33 |

| 40 | 40 | 260 | 32 | 48.3 | 70 | 120 | 190 | 43 |

| 50 | 40 | 300 | 40 | 60.3 | 88.9 | 127 | 190 | 44 |

| 65 | 25 | 300 | 50 | 76.1 | 101.6 | 159 | 280 | 62 |

| 80 | 25 | 300 | 65 | 88.9 | 121 | 171 | 280 | 68 |

| 100 | 25 | 325 | 80 | 114.3 | 146 | 218 | 280 | 101 |

| 125 | 25 | 325 | 100 | 139.7 | 177.8 | 252 | 400 | 101 |

| 150 | 25 | 350 | 125 | 168.3 | 219.1 | 272 | 600 | 107 |

| 200 | 25 | 400 | 150 | 219.7 | 273 | 300 | 900 | 123 |

| 250 | 25 | 520 | 200 | 273 | 355 | 451 | 236 | 122 |

| 300 | 25 | 635 | 250 | 323.9 | 455 | 572 | 280 | 155 |

| 350 | 25 | 650 | 300 | 355.6 | 508 | 697 | 325 | 187 |

| 400 | 25 | 762 | 350 | 406.4 | 610 | 764 | 466 | 221 |

| 500 | 16 | 914 | 400 | 508 | 680 | 810 | 466 | 211 |

| 600 | 16 | 1067 | 500 | 610 | 830 | 966 | 325 | 259 |

relevant information

Tel

0577-67113630 15857947467Add

Puyi Village Jiangbei Street Yongjia County Wenzhou City Zhejiang Province

Scan