Location:Home / Product / Ball Valve / Fixed electric stainless steel ball valve

Electric fixed ball valve is a new generation of high-performance ball valve on the market, generally suitable for long-distance pipelines and general industrial pipelines. At the beginning of its design, engineering personnel have made special considerations to ensure its safety, strength requirements, and suitability in harsh environmental conditions, making it a variety of corrosive and non corrosive media.

Compared with traditional floating ball valves, its advantages are more obvious. The ball of a traditional floating ball valve is floating, and under the action of medium pressure, the ball will undergo a certain displacement and be tightly pressed against the sealing ring at the outlet end, ensuring the sealing of the outlet end. It belongs to a single-sided forced sealing product, while the ball of a fixed ball valve is fixed, and under the action of medium pressure, the ball will not shift. In the design, there is sufficient pre tension in the two sealing rings to ensure sealing, which belongs to double-sided forced sealing.

Fixed ball valve characteristics:

The performance advantages of fixed ball valves are more obvious. People can operate them with ease because the ball is supported by upper and lower bearings, reducing friction and eliminating the huge resistance formed by inlet pressure and sealing left. As a fixed ball valve, in order to prevent displacement, its sealing performance needs to be strengthened. Therefore, reliable sealing performance is its two major performance advantages, because even if the sealing surface wears out during use, it can still maintain good sealing performance under the action of the spring. Moreover, the fireproof structure of the fixed ball valve is particularly special, and the fire resistance test meets certain standard requirements. The automatic pressure relief function is also not available in traditional floating ball valves, and the next important function is the drainage pipeline. The valve body is equipped with drainage holes on the upper and lower military emblem, which can check whether the valve seat is leaking at any time. In the working group, if the valve is in the fully open or fully closed state, the packing can be directly replaced, and the residual material in the pipeline can be discharged to reduce the pollution of the medium to the valve.

Reference standard for fixed ball valve products:

Design and Manufacturing: GB12237-89, API 6D, JPI7S-48

Flange dimensions: JB79-59, SH3406, GB9113, HG20592-97

ANSI B 16.5、JIS B 2212-2214

Structural length: GB12221-89, ANSI B 16.10, JIS B2002

Testing and Inspection: GB/T13927-89, JB/T9092-99, API 598

Electric fixed ball valve product usage:

The PTFE sealed ball valve is suitable for cutting off or connecting media on pipelines in various working conditions such as petroleum, chemical, and thermal power plants with a working temperature of -28~300 ℃. Applicable media include corrosive and strongly oxidizing media such as water, steam, oil, nitric acid, acetic acid, urea, etc. The operation modes include manual, pneumatic, electric, hydraulic, and pneumatic hydraulic linkage.

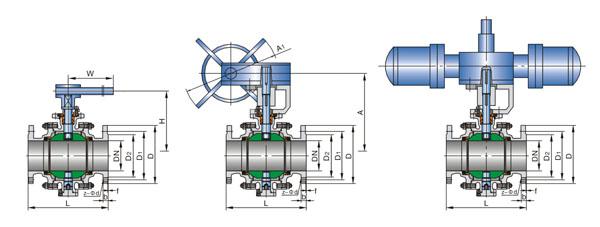

Structural characteristics of electric fixed ball valve products:

1. Long service life, self-lubricating polytetrafluoroethylene material is selected for the sealing ring. The micro friction between the sphere and the sealing ring effectively improves the service life.

2. Small size, light weight, easy to install and maintain.

3. The fixed ball valve structure can be installed in any direction and at any part of the pipeline.

4. V-shaped overlapping axial packing, achieving anti-corrosion A-level sealing.

1、 Administer Standard:

| DesignandManufacture | FaceToFace | FlangeDimension | PressureTemperatureLating | InspectionAndTest |

| GB122237 | GB12221 | GB9113JB79 | GB9131 | GB/T13927JB/T9092 |

2、 Pressure Test:

| NominalPressure | 1.6 | 2.5 | 4.0 |

| ShellTest | 2.4 | 3.8 | 6.0 |

| WaterSealTest | 1.8 | 2.8 | 4.4 |

| AirSealTest | 0.4-0.7 | ||

3、Main Part Materials and Property:

| Body | WCB | ZG1Cr18Ni9Ti | CF8 | CF3 | ZG1Cr18Ni12Mo2Ti | CF8M | CF3M |

| BallStem | 2Cr13 | 1Cr18Ni9Ti | 304 | 304L | 1Cr18Ni12Mo2Ti | 316 | 316L |

| Seat | PTFE PTFE+Glass PPL | ||||||

| Shim | PTFE StainlessSteel/flexibleGraphite ToothProfileGasket | ||||||

| StemSeat | PTFE StainlessSteel/FlexibleGraphite | ||||||

| Packing | PTFE EnhancedFlexibleGraphite | ||||||

| Gland | WCB | 1Cr18Ni9Ti | 304 | 304L | 1Cr18Ni12Mo2Ti | 316 | 316L |

| Temperature | -29~150(PTFE)-29~200(PTFE+GLASS)-29~300(PPL) | ||||||

| Medium | Watersteam Oilgoods | NitricAcid | strongeyoxidablemedium | AceticAcid | Urea | ||

4、 Size Main Dimensions:

| 1.6MPa | DN | L | D | D1 | D2 | b | n-d | H0 | H1 | H2 |

| RF Q947F 16C 16P 16R | 32 | 140 | 135 | 100 | 78 | 16 | 4-18 | 30 | - | - |

| 40 | 165 | 145 | 110 | 85 | 16 | 4-18 | 32 | - | - | |

| 50 | 178 | 160 | 125 | 100 | 16 | 4-18 | 43 | - | - | |

| 65 | 190 | 180 | 145 | 120 | 18 | 4-18 | 70 | - | - | |

| 80 | 203 | 195 | 160 | 135 | 20 | 8-18 | 110 | - | - | |

| 100 | 305 | 215 | 180 | 155 | 20 | 8-18 | 150 | - | - | |

| 125 | 356 | 245 | 210 | 185 | 22 | 8-18 | 200 | - | - | |

| 150 | 394 | 280 | 240 | 210 | 24 | 8-23 | 230 | - | - | |

| 200 | 457 | 335 | 295 | 265 | 26 | 12-23 | 260 | - | - | |

| 250 | 533 | 405 | 355 | 320 | 30 | 12-25 | 283 | - | - | |

| 300 | 610 | 460 | 410 | 375 | 30 | 12-25 | 380 | - | - | |

| 350 | 686 | 520 | 470 | 435 | 34 | 16-25 | 425 | - | - | |

| 400 | 762 | 580 | 525 | 485 | 36 | 16-30 | 492 | - | - | |

| 500 | 914 | 705 | 650 | 608 | 44 | 20-34 | 555 | - | - | |

| 600 | 1067 | 840 | 770 | 718 | 48 | 20-41 | 675 | - | - | |

| 700 | 1245 | 910 | 940 | 788 | 50 | 24-41 | 850 | - | - |

5、Size Main Dimensions:

| 2.5MPa | DN | L | D | D1 | D2 | b | n-d | H0 | H1 | H2 |

| RF Q947F 25 25P 25R | 32 | 180 | 135 | 100 | 78 | 18 | 4-18 | 30 | - | - |

| 40 | 190 | 145 | 110 | 85 | 18 | 4-18 | 32 | - | - | |

| 50 | 216 | 160 | 125 | 100 | 20 | 4-18 | 43 | - | - | |

| 65 | 241 | 180 | 145 | 120 | 22 | 8-18 | 70 | - | - | |

| 80 | 283 | 195 | 160 | 135 | 22 | 8-18 | 110 | - | - | |

| 100 | 305 | 230 | 190 | 160 | 24 | 8-23 | 150 | - | - | |

| 125 | 381 | 270 | 220 | 188 | 28 | 8-25 | 200 | - | - | |

| 150 | 403 | 300 | 250 | 218 | 30 | 8-25 | 230 | - | - | |

| 200 | 502 | 360 | 310 | 278 | 34 | 12-25 | 260 | - | - | |

| 250 | 568 | 425 | 370 | 332 | 36 | 12-30 | 283 | - | - | |

| 300 | 648 | 485 | 430 | 390 | 40 | 16-30 | 380 | - | - | |

| 350 | 762 | 550 | 490 | 448 | 44 | 16-34 | 425 | - | - | |

| 400 | 838 | 610 | 550 | 505 | 48 | 16-34 | 492 | - | - | |

| 500 | 991 | 730 | 660 | 610 | 52 | 20-41 | 555 | - | - | |

| 600 | 1143 | 840 | 770 | 718 | 56 | 20-41 | 675 | - | - | |

| 700 | 1346 | 955 | 875 | 815 | 60 | 24-48 | 850 | - | - |

6、Size Main Dimensions:

| 4.0MPa | DN | L | D | D1 | D2 | D6 | b | n-d | H0 | H1 | H2 |

| RF Q947F 40 40P 40R | 32 | 180 | 135 | 100 | 78 | 66 | 18 | 4-18 | 30 | - | - |

| 40 | 190 | 145 | 110 | 85 | 76 | 18 | 4-18 | 32 | - | - | |

| 50 | 216 | 160 | 125 | 100 | 88 | 20 | 4-18 | 43 | - | - | |

| 65 | 241 | 180 | 145 | 120 | 110 | 22 | 8-18 | 70 | - | - | |

| 80 | 283 | 195 | 160 | 135 | 121 | 22 | 8-18 | 110 | - | - | |

| 100 | 305 | 230 | 190 | 160 | 150 | 24 | 8-23 | 150 | - | - | |

| 125 | 381 | 270 | 220 | 188 | 176 | 28 | 8-25 | 200 | - | - | |

| 150 | 403 | 300 | 250 | 218 | 204 | 30 | 8-25 | 230 | - | - | |

| 200 | 502 | 375 | 320 | 282 | 260 | 38 | 12-30 | 260 | - | - | |

| 250 | 568 | 445 | 385 | 345 | 313 | 42 | 12-34 | 283 | - | - | |

| 300 | 648 | 510 | 450 | 408 | 364 | 46 | 16-34 | 380 | - | - | |

| 350 | 762 | 570 | 510 | 465 | 422 | 52 | 16-34 | 425 | - | - | |

| 400 | 838 | 655 | 585 | 535 | 474 | 58 | 16-41 | 492 | - | - | |

| 500 | 991 | 755 | 670 | 612 | 576 | 62 | 20-48 | 555 | - | - | |

| 600 | 1143 | 890 | 795 | 730 | 678 | 62 | 20-54 | 675 | - | - | |

| 700 | 1346 | 995 | 900 | 835 | 768 | 68 | 24-54 | 850 | - |

relevant information

Tel

0577-67113630 15857947467Add

Puyi Village Jiangbei Street Yongjia County Wenzhou City Zhejiang Province

Scan